Top Precision Fluid Component Connector Manufacturers for Medical, Biopharma, Dental and more!

Top Precision Fluid Component Connector Manufacturers for Medical, Biopharma, Dental and more!

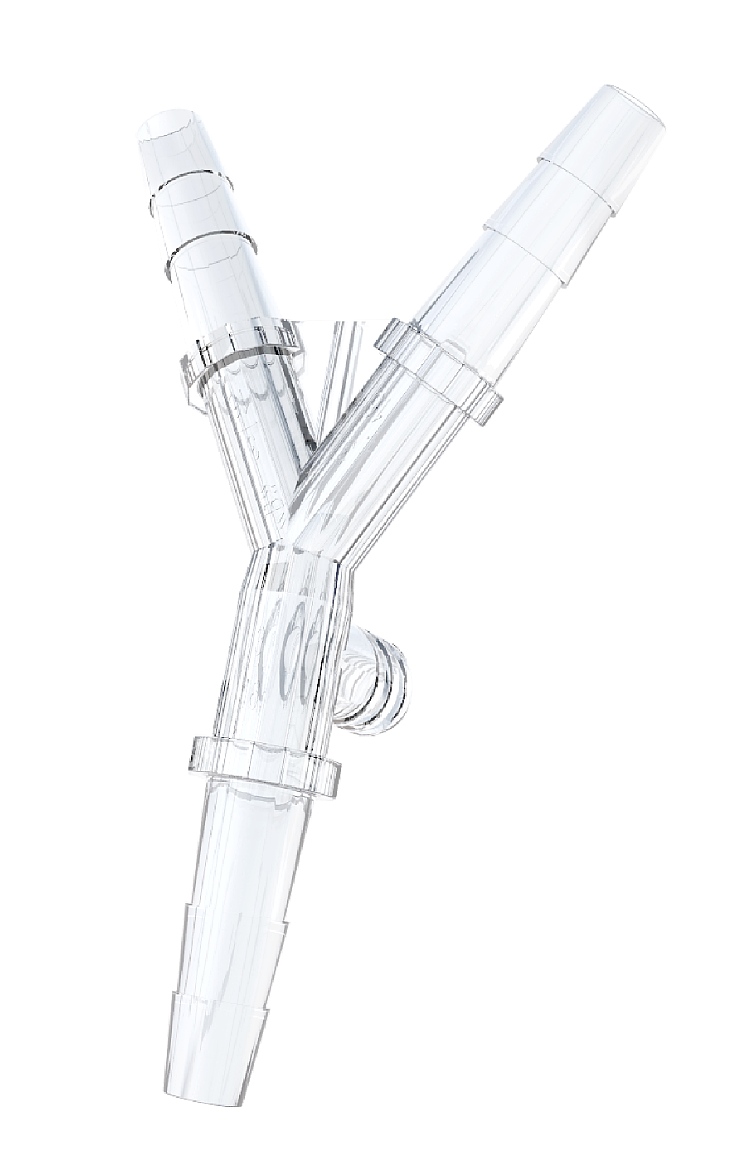

In applications demanding exact angles and uncompromised structural integrity, Brevet’s 60° Polycarbonate Y-Connectors deliver exceptional performance. Designed for specialized fluid routing, these rigid Y-connectors provide a precise 60° branching angle, optimizing flow dynamics and ensuring seamless integration into complex systems. Crafted from high-grade, non-flexible polycarbonate, our connectors offer superior strength, optical clarity, and chemical resistance, making them the ideal choice for applications where custom angles and unwavering reliability are paramount.

Brevet’s 60° Polycarbonate Y-Connectors are meticulously engineered to provide a fixed, optimal angle for diverting or combining fluid streams with high precision. Unlike flexible connectors, their rigid design ensures consistent alignment and flow, making them indispensable for systems where exact geometry and structural stability are critical. Ideal for demanding environments, these rigid fluid connectors support controlled flow and secure connections, enhancing overall system efficiency and safety.

Brevet 60° Y-Connectors are expertly crafted from high-performance polycarbonate, a material renowned for its exceptional properties in demanding applications.

Brevet’s manufacturing process for 60° Polycarbonate Y-Connectors epitomizes our commitment to unwavering quality and meticulous precision, crucial for fixed-angle components:

Wide and diverse aray of applications

Brevet's Y-Connectors are excellent for connecting multiple lines to and from dental units, enabling efficient dental fluid delivery and air management in various procedures.

Used in bioprocess fluid routing for media preparation, buffer management, and single-use assemblies where precise, non-collapsible fluid paths are mandated. Ideal for biopharma Y-connectors ensuring exact angular flow.

Crucial in complex medical fluid management systems requiring angled connections for IV lines, respiratory circuits, and specialized diagnostic equipment where rigid, fixed pathways are necessary for accurate delivery and monitoring. Essential for medical polycarbonate connectors requiring specific flow angles.

Perfect for bespoke fluid systems where the 60-degree angle provides an optimized solution for space constraints or specific equipment integration needs.

Employed in industrial applications demanding robust, rigid connectors for specific angular fluid or gas distribution where flexibility is not desired.

Providing precise branching in laboratory equipment, chromatography systems, and analyzers that require consistent fluid flow at specific angles for accurate testing and results. Critical for precision fluid routing in lab settings.

Our engineering team is ready to collaborate with you to develop a tailored

Y-Connector Solution!

Detailed dimensions and packaging information for our Polycarbonate Y-Connectors. Brevet Polycarbonate Y-Connectors are available in a variety of sizes to fit different tubing inner diameters. Please refer to the Polycarbonate Y Connector chart below for dimensions specifics as well as part numbers. For Custom connectors and contract manufacturing, click here.

Replace XX with suffix below based on material choice

-01 Covestro 2558-550115 Clear

-03 Covestro 2530-451118 Radiation stable tint

Will consider validating other polycarbonate material options for custom orders

| 125-XX | 142-XX |

| 129-XX | 127-XX |

| 133-XX | 131-XX |

| 137-XX | 135-XX |

| 141-XX | 139-XX |

| 126-XX | 128-XX |

| 130-XX | 132-XX |

| 134-XX | 136-XX |

| 138-XX | 140-XX |

The primary advantage is its rigid, fixed 60° angle, which ensures precise fluid routing and structural stability. This makes it ideal for applications where exact geometry, high pressure, and non-collapsible pathways are critical, unlike flexible connectors that can bend.

Yes, our 60° polycarbonate Y-connectors are manufactured from medical-grade polycarbonate and are FDA compliant and ISO 13485 certified, making them highly suitable for demanding medical fluid management and biopharmaceutical processing where purity and integrity are paramount.

Yes, polycarbonate offers excellent mechanical strength and rigidity, allowing our 60-degree Y-connectors to perform reliably in systems requiring higher pressure resistance compared to more flexible materials.

Polycarbonate Y-Connectors are generally low-maintenance due to their rigid and durable nature. Regular visual inspection for any signs of physical damage, cracks, or wear is recommended, particularly at connection points. The lifespan of these connectors is influenced by the specific application, operating conditions (e.g., temperature, pressure, chemical exposure, sterilization cycles), and proper installation guidelines. Their robust design typically offers extended durability in demanding environments. The lifespan of unsterilized polycarbonate is undetermined.

We utilize advanced precision injection molding techniques and rigorous quality control throughout our manufacturing process. This ensures that each polycarbonate Y-connector maintains its exact 60-degree angle and tight dimensional tolerances, critical for consistent performance.

Brevet offers two key polycarbonate material options: Polycarbonate 2558-550115 (clear) for transparency in standard applications, and Makrolon® Rx2530-451118 (purple). The purple Rx2530 is highly preferred for critical and sensitive uses due to its superior biocompatibility, enhanced sterilization resistance, and distinct visual identification.

Absolutely. We specialize in custom connector solutions. If your application requires a polycarbonate Y-connector with a specific angle other than 60 degrees, or unique features, our engineering team is ready to collaborate with you to design and manufacture a tailored solution.

Precision and quality are paramount. We start with meticulously designed and fabricated molds, often made from hardened steel. During the molding process, we maintain precise control over parameters like melt temperature, injection pressure, and cooling times, coupled with the use of high-grade polycarbonate resins. Following molding, the parts undergo a controlled annealing process in specialized ovens to relieve internal stresses and prevent potential stress cracking, ensuring optimal material integrity, long-term durability, and tight dimensional tolerances for every component.

Brevet’s Contract Manufacturing will create the perfect supportive Y-Connector 60° to your specifications.