Top Precision Fluid Component Connector Manufacturers for Medical, Biopharma, Dental and more!

Top Precision Fluid Component Connector Manufacturers for Medical, Biopharma, Dental and more!

It is a long and high-stakes journey from a single cell in a lab, to that of a life-saving vial in a hospital. Along this path, valuable fluids have to be moved, mixed, filtered, and filled usually hundreds of times.

In the world of biopharma, the focus is usually on the “big” technology. That consists of the massive bioreactors, or the complex chromatography columns. But the success of those machines relies entirely on the humble connections between them. If even one connector leaks, cracks, or introduces a contaminant, the science will stop.

At Brevet, we view our PVC connectors not just as plastic components, but as the guardians of your fluid path. Here is how they protect product integrity from the first culture to the final seal

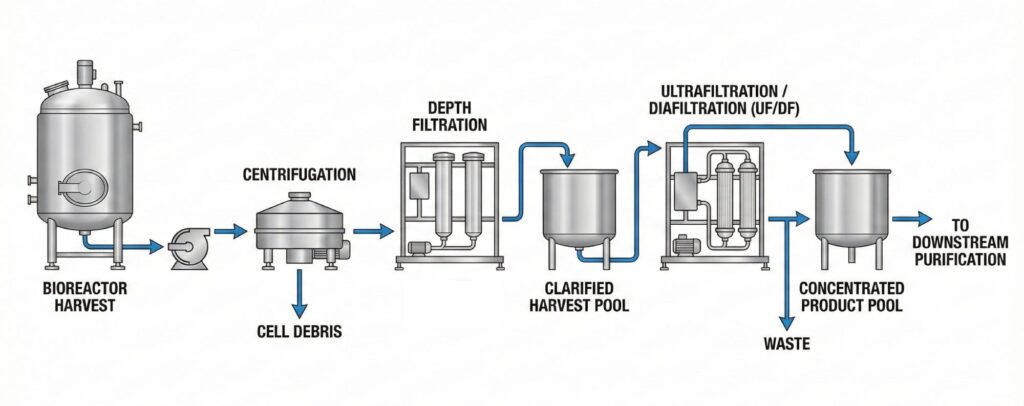

The upstream phase is all about nurturing growth. Whether you are working with mammalian cells or microbial fermentation, the environment really does have to be perfect.

Brevet’s connectors are designed with smooth internal geometry specifically to reduce shear stress. Cells are fragile and any turbulent flow through a poorly designed connector can damage them. This then will ruin viability before you even get started. Our connectors ensure that nutrient delivery and aseptic sampling happen gently, keeping the focus on cell health instead of attention on equipment troubleshooting.

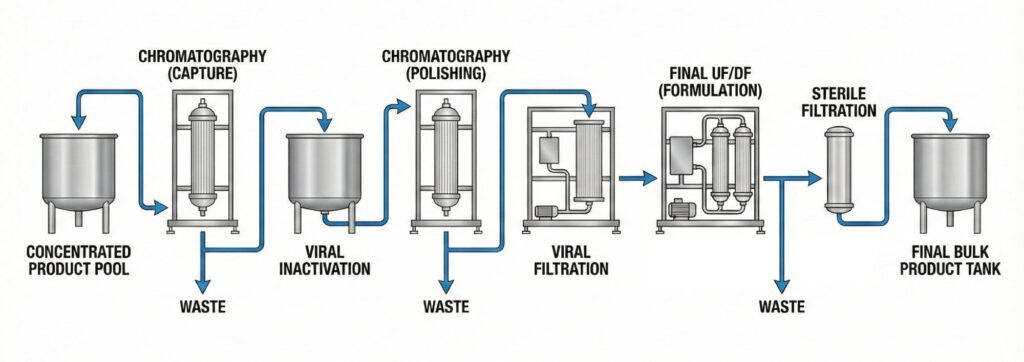

As biologics move into purification, the plumbing gets complicated. You are dealing with filtration, chromatography, and buffer management, often simultaneously.

This is where smart connector design saves the day. Our Y-connectors and manifolds simplify tubing routing, turning a “spaghetti tangle” of tubes into an organized system. We also offer color-coded options, which introduces a human-centric safeguard: it’s much harder for an operator to hook up the wrong buffer line when the connector is color-matched to the port.

By the time you reach fill-finish, the liquid flowing through the tubes is incredibly valuable. There is no room for error.

Brevet’s connectors support GMP compliance by ensuring a secure, leak-free transfer into vials, syringes, or final packaging. Because our PVC options range from rigid to flexible, they can adapt to the specific mechanical needs of filling machines without kinking or collapsing. This ensures the final step of the journey is as safe as the first.

One of the biggest headaches in bioprocessing is the “scale-up gap”—when the tubing and connectors that worked on the benchtop don’t fit the machinery on the production floor. Brevet connectors bridge that gap because PVC is uniquely adaptable.

For the Lab (Small Scale): We can prototype custom micro-connectors for intricate, low-volume tubing setups used in early-stage R&D.

For Production (Large Scale): As you move to pilot and commercial manufacturing, we can replicate those same geometries in larger bore sizes to handle high-flow requirements.